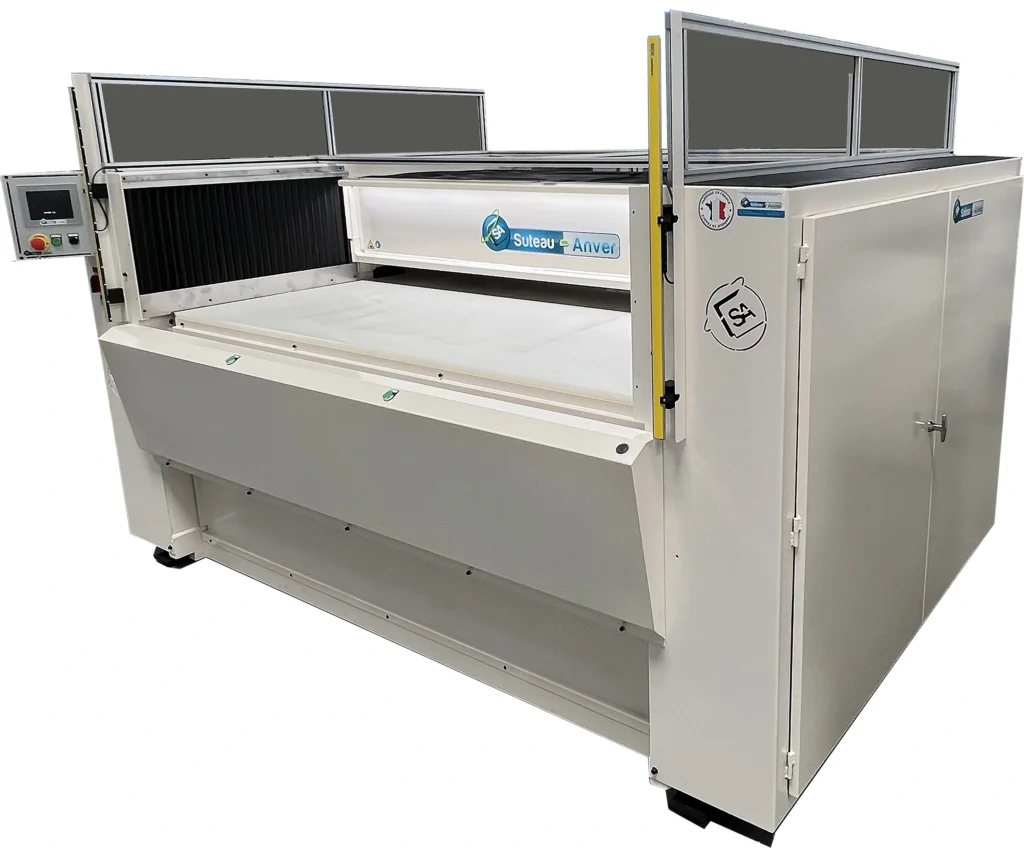

Receding head die-cutting press – Model PTMV

Receding head hydraulic die-cutting machine model PTMV: Precision and Efficiency in every Cut

Welcome to the future of die-cutting with our state-of-the-art Receding Head Hydraulic Die-Cutting Machine, Model PTMV. Designed and manufactured with over 75 years of expertise in the flexible materials industry, this machine is a true testament to our commitment to innovation and quality.

This extreme efficiency of this solidly-built press, specially designed for cutting any non-metallic material, depends on its built-in hydraulics.

A horizontal moving beam moves forwards and back for each cut on a hydraulic cylinder, leaving the entire cutting area free and enabling the operator to position his die and remove the cut-outs. As an option, if required, the die can be attached to the face of the beam and in that case the operator collects only the cut out pieces. In other words, on this machine, the counterpunches can be situated either on the beam or on the rising table.

The return distance of the beam is adjustable on the tactile screen in increments of 100 mm (parametrable). The table rises vertically to meet the beam when the beam is in the forward position.

Easy to use thanks to its touch-screen interface this receding head cutting press guarantees productivity, efficiency, minimum maintenance and safety for your production operators.

Key Features

- Hydraulic Die-Cutting Press: Experience unparalleled precision and power with our advanced hydraulic system. This feature ensures smooth, efficient, and consistent die-cutting for a variety of materials.

- Receding Beam Die-Cutting Machine: Our unique receding beam design maximizes workspace and accessibility. The horizontal moving beam retracts after each cut, allowing for easy positioning of dies and removal of cutouts. This enhances productivity and safety, making the PTMV model an ideal choice for high-volume operations.

- Robust Construction and User-Friendly Interface: Built with mechanical welding for longevity, and equipped with a touch-sensitive, multi-language interface, the PTMV ensures ease of use and minimal maintenance.

- High Cutting Accuracy and Speed: Achieve precise cuts with high production rhythm. Our machine offers cutting accuracy and speed tailored to your specific industry needs, ensuring that you can meet your production goals without compromising on quality.

- Versatility in Materials and Sectors: Whether it’s rubber, leather, foam, textiles, or composites, the PTMV handles a variety of materials. It’s perfectly suited for sectors ranging from automotive to furniture, packaging to medical, ensuring versatility across industries.

- Customizable Options and Made in France: Tailor the machine to your specific requirements with a range of options, and take pride in a product that’s designed and manufactured in France, ensuring adherence to the highest standards of quality and craftsmanship.

Your Partner in Excellence

Choosing the Receding Head Hydraulic Die-Cutting Machine Model PTMV means choosing a partner in excellence. Our dedication to providing the best in die-cutting technology is reflected in every aspect of this machine. Elevate your production capabilities and experience the difference in precision, efficiency, and quality with the PTMV.

Technical features

| Electrical energy: | 400 Volts three-phase + Neutral + Earth 50hz |

| Speed of the beam, forward and back: | 56 m/mn |

| Accuracy of beam stop: | +/-10 mm |

| Approach speed: | 167 mm/s not adjustable |

| Cutting speed: | 22 mm/s not adjustable |

| Opening speed: | 198 mm/s not adjustable |

| Stroke: | 70 mm |

| Daylight between table and beam (without die and without block): |

110 mm |

| Height of the work surface: | 940 mm |

Options

- Feeding systems

- Unwinders

- Dimmable lighting

- Die-holder above the beam

- Die-holder under the beam

- Machine without front cover

- Mechanical posi-stops

- Soundproofing

- Painting on request

- Cutting block / die clamping systems

- Servo-pump

Available versions

- Available in an EC standard / three phase.

- Available in 100% electrical

Useful working area and cutting power

- 1000×500 mm | 25 tons

- 1600×600 mm | 40 tons

- 2000×800 mm | 70 tons

- 2000×900 mm | 100 tons